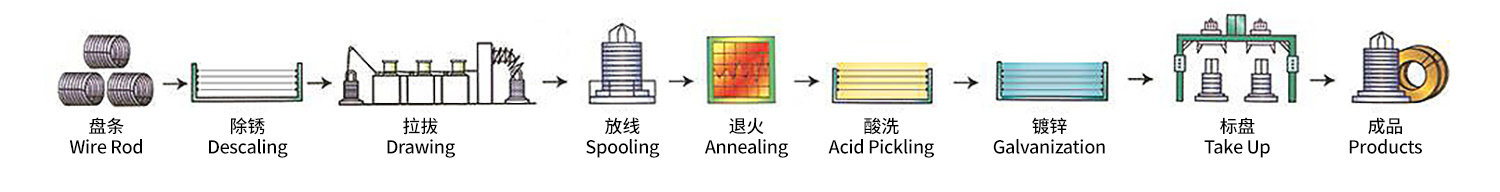

How Galvanized Steel Wire Is Produced?

Galvanized steel wire production involves a series of meticulous steps to ensure quality and durability.

1.Wire Rod

The process begins with high-quality steel wire rods.

2.Descaling

Descaling is performed to remove any oxide formation on the steel rods. Acids like Hydrochloric Acid are used to eliminate scale and impurities.

3.Drawing

The drawn wire is pulled through a series of dies to achieve the desired diameter. This drawing process enhances the wire's strength and consistency.

4.Spooling

Spooling involves winding the wire onto spools for further processing. It facilitates the handling and transportation of the wire.

5.Annealing

The wire undergoes annealing, a heat treatment process that enhances its ductility and removes internal stresses. This step ensures the wire's flexibility and durability.

6.Acid Pickling

Acid pickling is employed to remove any remaining scale, rust, or oxides on the wire's surface. This process helps prepare the wire for galvanization.

7.Galvanization

The wire is immersed in a bath of molten zinc during the galvanization process. This forms a protective zinc coating on the wire, providing corrosion resistance.

8.Take-Up

After galvanization, the wire is cooled and taken up, referring to the process of winding the galvanized wire onto spools or reels for storage or transportation.

9.Final Products

The final products include galvanized steel wire spools, coils, or other customized forms suitable for various applications.

This detailed process ensures the production of high-quality galvanized steel wire with excellent corrosion resistance and mechanical properties.

Previous Page

Previous Page

3D Virtual Pavilion

Douyin Official Media

Flagship Micro Mall

WeChat Public Number

CONTACT US

Email : enquiry@jiuzhoumetal.com

Mobile: +86-15966669999

Wechat: +86-15966669999

Whatsapp: +86-15966669999

Tel : +86-531-86888888

Address : China Resources Land Plaza, Lixia District, Jinan City, Shandong Province